Safety First: Managing Dust and Water in Drilling Operations

In construction and heavy-duty maintenance environments, drilling is a fundamental operation used across a variety of trades, from electrical and plumbing installations to core sampling and heavy anchor placement. While the focus is often placed on performance and output, the management of drilling by-products, namely respirable dust and drilling water, is paramount to ensuring safety, tool longevity, regulatory compliance, and productivity on-site.

This guide provides an in-depth technical overview of managing safety risks during wet and dry drilling, covering the science of dust extraction, legal requirements, and dust suppression methods, alongside water containment systems and best practice strategies for Personal Protective Equipment (PPE).

1. The Dual Hazards of Drilling: Dust and Water

Dry Diamond Core Drilling

Dry diamond core drilling through materials such as reinforced concrete, granite, mortar, and brick produces significant quantities of airborne particulates, including respirable crystalline silica (RCS). Particles smaller than 10 microns can be inhaled deep into the lungs.

These health risks are cumulative and irreversible, making exposure control essential. According to the UK Health & Safety Executive (HSE), exposure to RCS dust must be reduced as far below the Workplace Exposure Limit (WEL) of 0.1 mg/m³ (8-hour TWA) as is reasonably practicable.

Wet Diamond Core Drilling

Wet diamond core drilling suppresses airborne dust at source but introduces new hazards:

- Slurry (a mixture of dust and water) creates slip risks and can obscure surfaces.

- Uncontrolled water flow may cause flooding, damage to substrate finishes, and corrosion.

- Electrical shock risk if water enters unsealed tool casings or junctions.

Therefore, both dry and wet drilling demand integrated safety solutions, not simply task-specific interventions.

2. Legal Framework for Dust Control in Drilling

Is Dust Extraction a Legal Requirement?

Yes. In the UK, the Control of Substances Hazardous to Health (COSHH) Regulations 2002 legally require that employers implement controls to reduce exposure to hazardous substances, including airborne dust from drilling. This obligation includes:

- Risk assessment

- Implementation of control measures (e.g., dust extractors)

- Health surveillance

- Worker training

Additionally, under PUWER (Provision and Use of Work Equipment Regulations), employers must ensure tools are maintained and appropriate for use with dust extraction systems.

3. Dust Extraction Systems: How They Work & Why They Matter

How Does a Dust Extraction System Work?

A professional-grade dust extraction system integrates several components:

- Dust hood: Mounted to the drilling machine, enclosing the cutting zone to capture dust at source.

- High suction vacuum unit: Creates negative pressure to pull dust away from the cutting interface.

- Filtration system: Typically involves multi-stage filtration, including HEPA (High-Efficiency Particulate Air) filters capable of trapping 99.97% of particles down to 0.3 microns.

- Auto-clean mechanisms: Use reverse air pulses or mechanical agitation to clean filters during operation, preventing blockages and maintaining airflow. EIBENSTOCK dust extractors also feature a patented self-cleaning system that operates automatically, with no need to press any buttons.

At EIBENSTOCK, we have a range of L & M class dust extraction vacuums that are compatible with our diamond core drills. Included in our range is a water recycling vacuum that suctions water to reduce dirt and wetness on site, alongside prolonging the life of your dust extraction system and its components.

Features a robust design body, construction site durable wheels, anti-static hoses & stainless steel tubes.

Equipped with power take-off function, 35L tank capacity and patented permanent filter cleaning for long-lasting performance.

Features an M-Class filter system, 35L tank capacity & patented permanent filter cleaning. Suitable for harmful dusts with limit values of ≥ 0.1mg/m³.

M-Class wet & dry vacuum with twin filters, automatic filter cleaning, large storage tray and high flow rate, increasing the filter life and offering high performing suction performance.

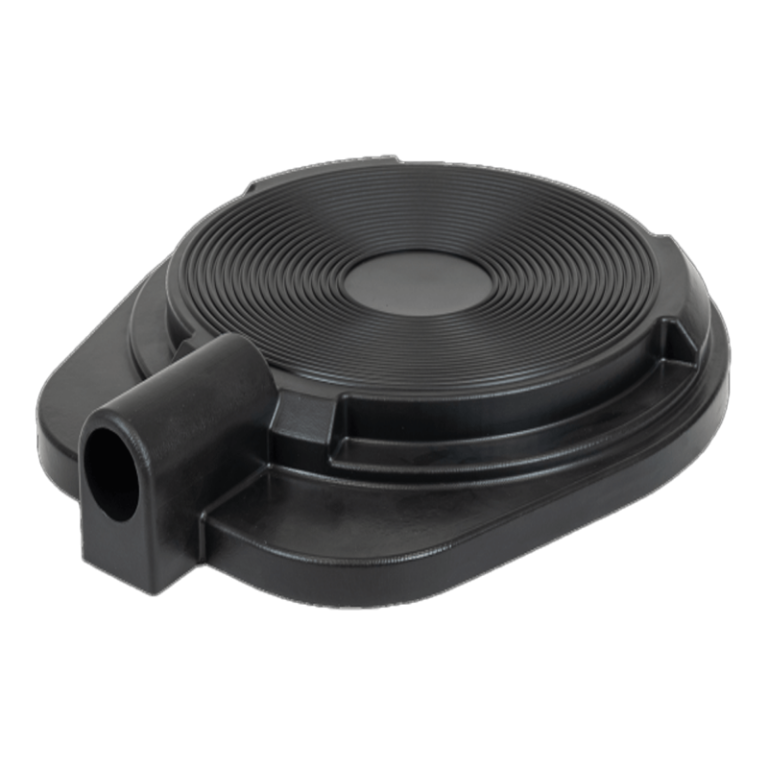

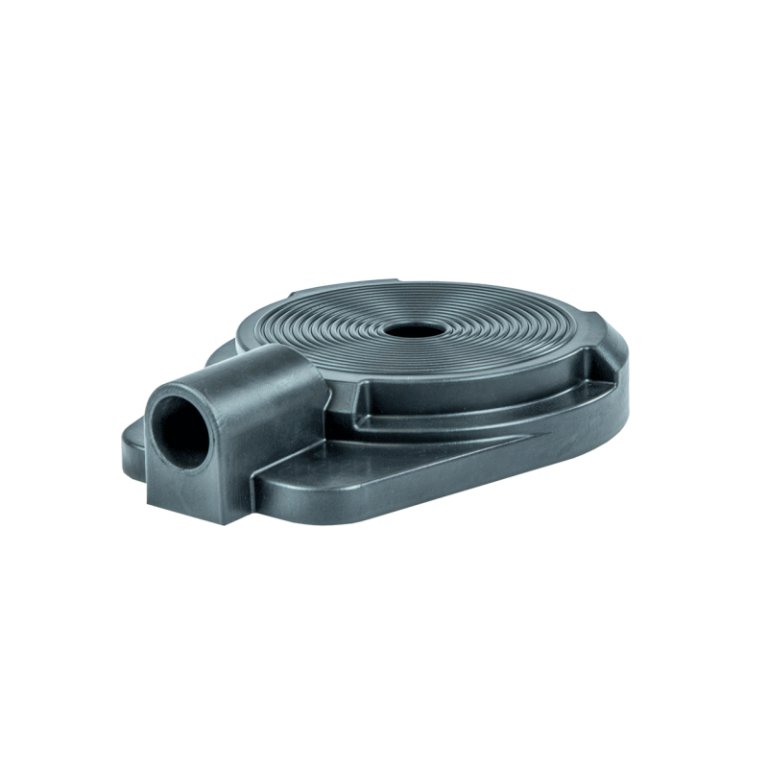

Universal dust ring suitable for both wet and dry diamond core drilling up to a maximum of 252mm.

Universal dust ring suitable for both wet and dry diamond core drilling up to a maximum of 162mm.

What Are The Different Types of Dust Extractors?

Dust extractors are classified by hazard class:

| Class | Application | Filtration Efficiency |

|---|---|---|

| L (Low) | Softwoods, non-toxic dust | >99.9% |

| M (Medium) | Hardwoods, silica dust, and concrete | >99.9% |

| H (High) | Carcinogenic dusts, asbestos and mould | >99.9995% |

For concrete, stone, and masonry, an M-Class extractor with automatic filter cleaning is the industry minimum.

4. Wet Drilling: Suppressing Dust While Containing Water

The Importance of Water in Wet Drilling

Water provides:

- Dust suppression: Reduces particle dispersion at the cutting surface.

- Thermal regulation: Prolongs the life of diamond segments found on cores and blades.

- Surface protection: Prevents cracking due to overheating.

However, volume and direction of water flow must be precisely controlled.

Water Feed & Recycling Systems

EIBENSTOCK drills, such as the PLD 182.1 are equipped for integrated wet operation:

- Water feed via quick coupling

- Pressure control valves

- Internal water swivel joints for uninterrupted flow

For site applications without mains supply, use pressurised water tanks or recyclable water feed systems to limit environmental impact.

Slurry Collection & Containment

- Attach to the substrate

- Capture water and slurry at the drill point

- Connect to wet vacuums for closed-loop systems

Wet & Dry Vacuums

- Stainless steel tanks

- Dual-stage filtration

- Corrosion resistance for concrete slurry

Explore wet and dry vacuums from EIBENSTOCK:

5. Personal Protective Equipment (PPE) Standards

PPE for Dry Drilling

- Respiratory Protection: P3 mask or Powered Air Purifying Respirator (PAPR) for high-dust tasks

- Eye Protection: EN166-certified goggles

- Hearing Protection: 85 dB+ tools require SNR 25+ ear defenders

- Cut-resistant Gloves: Improve control and safety

- Workwear: Anti-static, long-sleeved, dust-resistant fabric

PPE for Wet Drilling

- Waterproof Gloves: Nitrile or neoprene coated

- Non-slip Boots: EN ISO 20345-compliant with anti-perforation sole

- High Visibility Overalls: For dark/low-light workspaces

Safety Helmet: With chin strap for vertical operations

6. Maintenance and Inspection Protocols

Regular servicing ensures equipment remains within legal and operational safety thresholds. To minimise downtime, we also recommend keeping an extra set of filters on hand for both dry and wet drilling.

Dust Extractors:

- Daily inspections

- Empty the tank, check filters and test section

Water Feed System:

- Weekly inspections

- Inspect hoses, clean valves, and pressure test

Drilling Tools:

- Pre-task inspection

- Check shroud seals and motor vent cleanliness

PPE:

- Check before use

- Check the mask seal, glove integrity and helmet strap

All inspections should be logged per HSE PUWER compliance.

7. Engineering Controls vs PPE: Hierarchy of Controls

PPE should not be the primary defence. The most effective mitigation follows this order:

- Elimination – Use off-site prefabrication or alternative fastening if possible

- Substitution – Use wet drilling over dry if safe to do so

- Engineering Controls – Dust extractors, slurry containment, RCDs

- Administrative Controls – Training, signage, permit-to-work

PPE – Final barrier between the hazard and the user

Safer, Cleaner, Compliant Drilling

Whether you’re core drilling for mechanical systems or precision boring through reinforced concrete, dust and water management are non-negotiables. Poor control can lead to health issues, slip injuries, equipment failure, and legal penalties.

Explore EIBENSTOCK’S range of core drills, combined with high-performance dust extraction systems, that offer reliability, durability and safety for all site conditions.