Plaster Mixers Compared: Which Model Best Suits Your Needs?

Share

For professionals who demand precision, efficiency, and reliability, the choice of a plaster mixer can make or break the job. Whether you’re mixing adhesives for tiling, heavy polymer renders for external wall insulation, or gypsum plaster and repair mortars, the mixer between your hands can define the difference between smooth workflows and bottlenecks.

That’s where the EIBENSTOCK MEGAMIXER series shines, designed to meet the specific needs of plasterers, renderers, and tilers. In this guide, we compare the key models, MM19, MM20, MM21, MM22, MM29, MM30, and the twin‑paddle MZR24, examining power, ergonomics, mixing volume, speed control, and application suitability, to help you choose your perfect match.

Model-by-Model Deep Dive

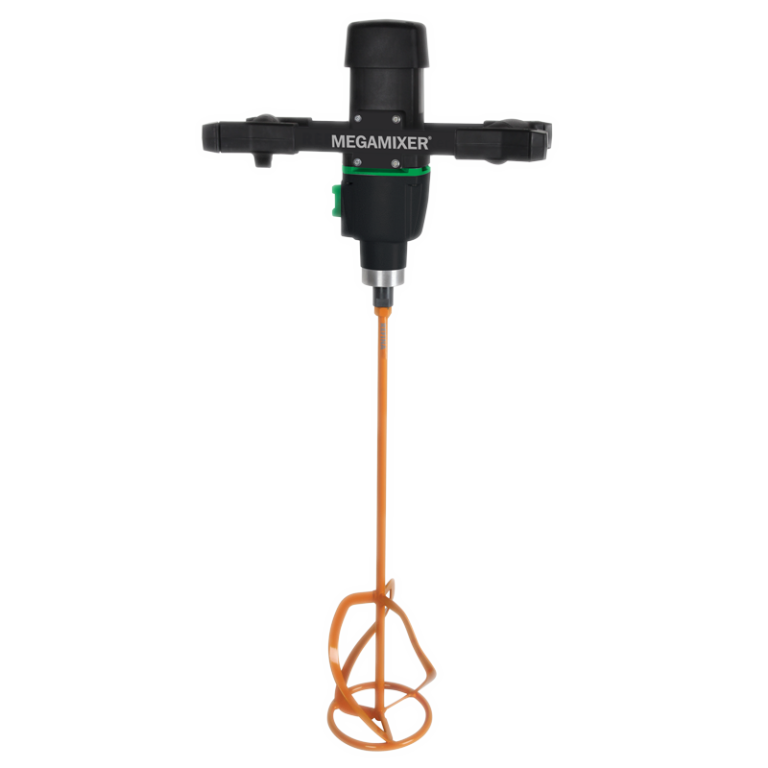

MM19 – Durable D Handle Paddle Mixer

- Ergonomics: The MM19 (and MM29) MEGAMIXERS feature a robust D-handle design, providing excellent balance and control during use. The ergonomic shape ensures a comfortable grip, reducing strain over extended mixing sessions. Combined with a front rubber bow handle, users benefit from added stability and comfort, even when working with heavier materials.

- Durable Motor: Powerful 1,050w motor equipped with a reliable gearbox and D-shaped handle.

- Ideal For: Specifically designed for mixing browning plasters, floor coatings, epoxy paints, bonding and drywall adhesives.

MM20 – Compact Power for Everyday Mixes

- Design & Motor: Built around a robust yet compact 1,100W motor, the MM20 is the single-speed workhorse for trades requiring nimble handling, whether mixing adhesives, thin-set mortars, or smaller batches of plaster.

- Ergonomics: Featuring an H‑handle design that ensures cable protection and an ergonomic mix posture. The soft start reduces initial splash, while the low-speed/high-torque gearing handles heavier mixes with ease.

Ideal For: One-man operations, tight job sites, or when working with lightweight materials where bulk mixing isn’t required.

MM19 MEGAMIXER

Durable D Handle Paddle Mixer

MM20 MEGAMIXER

Compact Power for Every Mix

MM21 – Medium Weight Plaster & Mortar Mixer

- Consistent Performance: Long-life, high torque gearbox designed for mixing materials up to 50kg.

- Ergonomic Handle: The H handle gives easy handling and a comfortable mix position, also helping to protect the power tool motor from damage.

- Soft Start: The MM21 is equipped with a soft start feature and variable speed, designed to minimise splashing when starting and provide lump-free mixes.

- MR3 Spiral Paddles: The paddle mixer is equipped with high-performance MR3 spiral paddles, with various paddle designs also available.

MM22 – Elevated Performance in a Lean Frame

- Power: A step up at 1,150 W with a durable two-speed gearbox, bringing both mixing power and control

- Handling: The H‑handle and soft-start system deliver smooth, splash-minimised starts. Interchangeable paddles accommodate a variety of material densities.

Who It’s For: Ideal for tradespeople balancing load size with portability, especially when lump‑free, consistent mixes are critical.

MM21 MEGAMIXER

Medium Weight Plaster & Mortar Mixer

MM22 MEGAMIXER

Elevated Performance In a Lean Frame

MM29 – Heavy-Duty Mixing, High Throughput

- High Torque Gearbox: Boasts a powerful 1,800 W motor with a single-speed, slow-turn/high-torque gearbox. The generated mixing speed is around 400 rpm and can handle up to 100 kg per batch, with a throughput of up to 1,200 kg/hr.

- Design Features: D‑handle and H‑handle hybrid ergonomics provide comfort with precision, while the spiral paddle ensures a consistent mix with minimal air entrainment

- Applications: The go-to for contractors dealing with heavy renders, polymer-infused repair mortars, epoxy/slurry mixes, and floor screeds. It delivers efficient high-volume output without compromising reliability.

MM30 – Tradespeople’s Trusted Heavy-Duty Mixer

- Performance: Also 1,800 W but enhanced with a two‑speed gearbox for finer control over mixing dynamics and built with safety modifications such as a lock‑button removal, dust‑protected switch, and reinforced cable handling.

- User Focus: Made for users who mix hefty loads (up to 80 kg) but want the flexibility of changing speeds to suit varied materials, from lightweight renders to dense adhesives

Best Fit: Plasterers and renderers demanding both power and adaptability across multiple materials and job types.

MM29 MEGAMIXER

Heavy Duty Mixing, High Output

MM30 MEGAMIXER

The Trade Favourite

MZR24 – Twin-Paddle Innovation for Viscous Mixes

- Unique Mechanism: Features twin contra-rotating paddles with positive mix action. This isn’t about power alone; it’s about achieving flawless mixes for fibre-filled pastes, heavy adhesives, and stubborn, viscous material blends.

- Handling & Safety: H-handle ergonomics, soft start, low splash – all engineered for demanding environments with challenging materials

Why Choose It: When normal spiral or paddle mixers struggle with texture, viscosity, or inclusions (like fibres or additives), the MZR24’s twin paddles deliver unmatched performance and reduced air entrainment.

MZR 24 TWIN PADDLE MEGAMIXER

Twin Paddle Innovation for Viscous Mixes

Browse The Full EIBENSTOCK Range

Explore the full range of EIBENSTOCK paddle mixers.

Comparative Table

| Model | Motor Power | Speed / Transmission | Ergonomics & Controls | Best For |

|---|---|---|---|---|

| MM19 | 1050 W | Single speed, high torque | D-handle, soft start | Finishing & backing coat plaster, EWI, mortars & epoxy, floor screeds & paints. For mixing materials up to 40kg |

| MM20 | 1100 W | Single speed, high torque | H-handle, soft start | Light renders, adhesives, and small plaster batches. For mixing materials up to 40kg |

| MM21 | 1150 W | Single speed, high torque | H-Handle, soft start | Medium loads, smooth mixing for general trades. For mixing materials up to 50kg |

| MM22 | 1150 W | Two-speed gearbox | H-handle, paddle options | Medium loads, smooth mixing for general trades. For mixing materials up to 50kg |

| MM29 | 1800 W | Single speed, slow, 400 rpm | D-/H-handle hybrid | Heavy renders, screeds, high-volume mixing. For mixing materials up to 80kg |

| MM30 | 1800 W | Two-speed gearbox | H-handle, safety upgrades | Heavy-duty, varied-viscosity materials. For mixing materials up to 80kg |

| MZR24 | 1800 W | Twin contra-rotating paddles | H-handle, low splash | Viscous, fibre-filled mixes. For mixing materials up to 80kg |

Choosing the Right Model for the Job

Tradespeople know that the right mixer isn’t just about brute strength; it’s about using the right tool for the material and volume at hand.

- Light, Everyday Mixes: Use the MM19 or MM20 if your workload involves smaller batches or light plastering tasks. Its compact build and smooth soft start make it user-friendly and economical.

- Versatile Mid-Range Performance: The MM21 or MM22’s mid-range power makes it ideal for most on-site requirements without being overkill, making it perfect for switching between lightweight and mid-density materials.

- Heavy Batching, Continuous Use: If your day involves frequent large-volume mixes (render, screed, epoxy), the MM29 delivers robust power with simple performance optimised for durability.

- Flexibility Meets Power: For heavy materials that require speed control, such as sanding plaster or polymer renders, the MM30 offers both power and modulation.

- Challenging, Viscous Materials: When mixing heavy fibre mortars, silicone-laden render, or thick pastes, the MZR24’s twin-paddle technology creates a consistent, air-free blend that single-spindle mixers can’t match.

Spend 30 seconds assessing your typical mix types and volumes. That clarity ensures you match the right EIBENSTOCK model to your trade, maximising productivity and reducing fatigue.

Invest Smart, Work Smarter

EIBENSTOCK’s MEGAMIXER lineup empowers tradespeople with tools engineered for performance, control, and enduring reliability, whether managing lightweight mixes on a tight schedule or heavy-duty rendering on demanding sites. The MM20 offers agile simplicity; the MM22 elevates it with multi-speed finesse; the MM29 and MM30 bring the muscle; and the MZR24 redefines mixing capability for tough, viscous materials.

Your work, plastering, screeding, rendering, or tiling, deserves the right mixer. Choose with purpose, and watch your work efficiency and quality of finish rise.