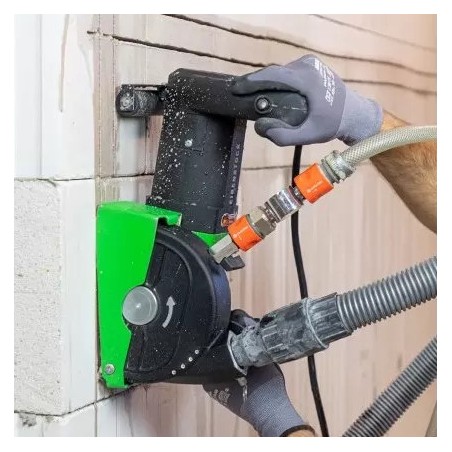

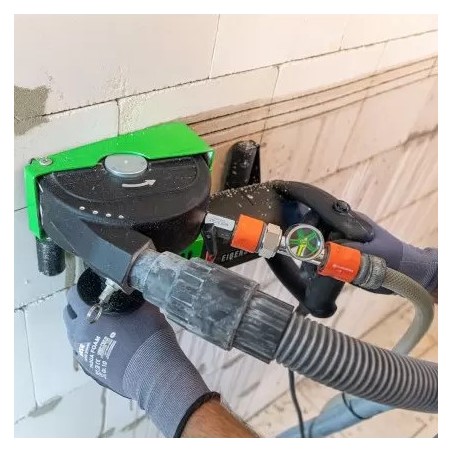

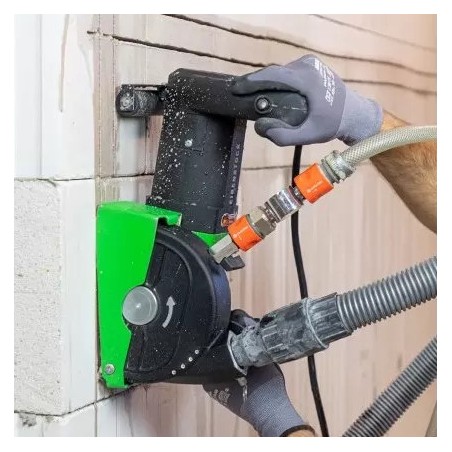

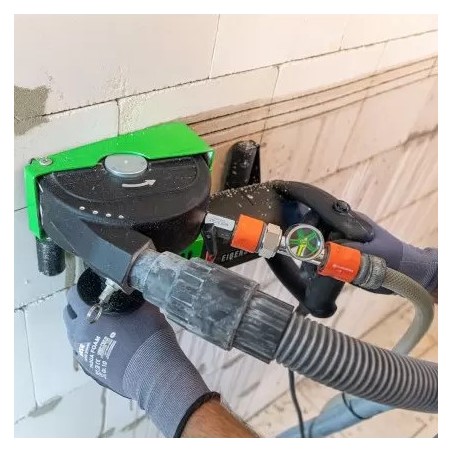

EMF 150.1 P 2300W 6" Twin Blade Wet/Dry Diamond Wall Chaser

The EIBENSTOCK EMF 150.1 P Wet/Dry Diamond Wall Chaser features the same reliability and cutting performance as its dry cutting counterpart, the EMF 150.1, with the addition of wet cutting allowing for dust-free cutting that is faster, more efficient and quieter compared to dry cutting. To begin wet cutting, plug the dust extraction outlet and adjust the water flow valve to match your cutting application. The EMF 150.1 P is a genuinely versatile wall chaser allowing for fast cutting in soft and hard materials. Additionally, if using a suitable dust extraction unit, the dust extraction outlet can be used while wet cutting to remove the wet slurry from the work surface for a superior clean working environment.

Features:

Data sheet

*wattage based on 230v rating

Segmented Diamond Cutting Disc 6", For Concrete & General Purpose

Turbo Diamond Cutting Disc 6", For concrete & general use

EDS 125 Wet/Dry Diamond Tile Cutter

ETR 400.2 P Opposite Cutting Wet Diamond Cutter

ERC 350 Multi Material Compact Portable Pipe Saw

EDS 181 8" Diamond Wet/Dry Stone & Tile Cutter

EMF 150.1 6" Twin Blade Diamond Wall Chaser

EMF 180.2 7" Twin Blade Diamond Wall Chaser

EMF 125.2 5" Twin Blade Diamond Wall Chaser

PCD disc 4" pointed segments for EPF 200-3